SpiroExpand pressurisation

Pressurisation is the key to a good system design. Our experience, research and targeted investigations have taught us that most issues within heating and cooling systems are closely related to insufficient pressurisation.

Often even straightforward problems are overlooked during design, installation, and maintenance. As a result, the system fluid’s quality is seriously compromised, and a potentially fatal series of events will occur. This dramatically reduces the efficiency of the system and causes premature failure of major system components.

Often it ends up in high operating costs for the plant and considerable expense for the owner and annoying inconveniences for the end-user. Parts need to be replaced, and the system must be cleaned persistently, and time and again, chemicals are applied. All this to achieve a “status quo” for the circulating fluid.

Breaking the cycle of work and costs starts with the pressurization system. A poorly designed, installed and maintained pressurization system can lead to negative pressures around the circuit. Air can be drawn in through automatic air vents, gaskets and micro leaks.

High pressure situations can lead to water being emitted through the safety valves and the subsequent frequent addition of further raw refill water. The introduction of fresh oxygen-rich water depletes any level of corrosion inhibitors that may be present. The onset of corrosion is then inevitable, and the cycle continues:

Corrosion inhibitors do not affect the content of inert gases such as nitrogen and carbon dioxide that are present in large volumes and reduce the operating efficiency of the system.

Each heating or cooling system puts different demands on a pressure control system. Also, operators place additional requirements on the equipment of the pressure control systems, on the possible signal exchange with other parts of the installation or control system and operational reliability.

SpiroExpand covers a full range of solutions, from the most basic setup to the most complicated system. If you can’t find the right plan for you, we’ll be happy to create a customised set up specifically for your problem.

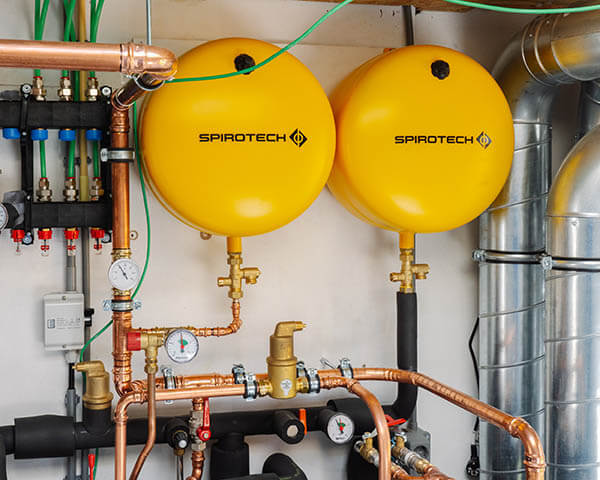

Using a pressurization unit means optimized pressure in your system

and saving space in your boiler room!

The SpiroExpand PicoControl Kompakt (EPCK) is available in 6 system versions , with different vessel volumes: 45, 75, 125, 200, 300 or 500 liters.

The working pressure range extends up to 4.0 bar.

The SpiroExpand PicoControl Kompakt is equipped with a single pump (SOLO, 1x 100%) and overflow valve (1x 100%).

The SpiroExpand Multicontrol Kompakt (EMCK) is available in 102 possible versions with 5 possible vessel volumes : 45, 75, 125, 300 or 500 liters. Two more barrels can be added.

The SpiroExpand MultiControl Kompakt is available with one (SOLO) or two (DUO 50% or Maxi 100%) pumps and an overflow valve. The DUO and MAXI can also be equipped with two overflow valves (TWIN). There are also a variety of partner packages available.

The SpiroExpand Multicontrol Modular (EMCM) is available in 75 system versions and with 12 vessel volumes from 200 to 10,000 litres. They can be expanded several times to larger volumes.

The SpiroExpand MultiControl Modular is available with one (SOLO) or two (DUO 50% or Maxi 100%) pumps and an overflow valve. DUO and MAXI can also be equipped with two overflow valves (TWIN). There are also a variety of partner packages available.

The SpiroExpand TopContol Modular (ETCM) is a modular expansion and pressure maintenance unit, available in 25 system versions, for combination with the pressureless EC expansion vessels (0.5 bar safety valve).

The SpiroExpand TopControl Modular is available with one (SOLO) or two (DUO 50% or Maxi 100%) pumps and an overflow valve. DUO and MAXI can also be equipped with two overflow valves (TWIN). There are also a variety of partner packages available.

The SpiroExpand Multicontrol Cool (EMCC) is available in 6 system versions and 4 drum volumes of 125, 200, 300 or 500 liters.

The SpiroExpand MB0650 is a top up pressurisation unit with a flow rate (up to 18.5 l/min max @1bar) and a 5 litre internal category 5 (AB air gap) break tank.

Available as a single pump configuration. With electronic pressure transducer and user-friendly microprocessor for use on sealed systems in order to provide a minimum system pressure requirement.

The unit is easy to install and commission and housed in a compact, enclosed unit, making it suitable for wall mounting.

Ideal for small commercial or large domestic applications.

Software updates should only be performed by our factory customer service or by trained service partners who are familiar with the devices and are aware of potential hazards and risks caused by software updates. In the event of non-conformity and direct or consequential damage, any warranty or warranty claim is excluded.

Note: During the implementation of the software update, the operation of the device is not guaranteed!

For the degassing of the system water, we recommend observing the guidelines VDI 4708 and VDI 2035-2. For the best possible degassing in heating and cooling systems, a separate vacuum degasser or microbubble air separator is required in addition to the pressure step degasser in the SpiroExpand expansion units.

The degassing function of the SpiroExpand units reduces air-related problems in closed water circuits, but is often insufficient to also remove dissolved gases from the system.

More information about Optimal Degassing

Our range of vacuum degassers Our range of microbubble air separators

In the document below you find 2 connection diagrams with the SpiroExpand MultiControl Kompakt Solo in combination with our vacuum degassers:

A SpiroTrap dirt separator with magnet is also added to the connection diagram to ensure that your system water will be free from dirt and magnetite at any time.

These are ‘passive’ pressure management systems. A preset gas pressure in the membrane expansion vessel is used for pressure control. Because membrane expansion vessels do not have a make-up function, we ideally combine this type of pressure control with a vacuum degasser including a make-up function.

The expansion tanks are available in 12 configurations and with volumes between 2 -3000 litre and an operational pressure range from 3.0 – 25 bar.